4D Printing: The Revolutionary Technology Creating Self-Transforming Materials (2025 Edition)

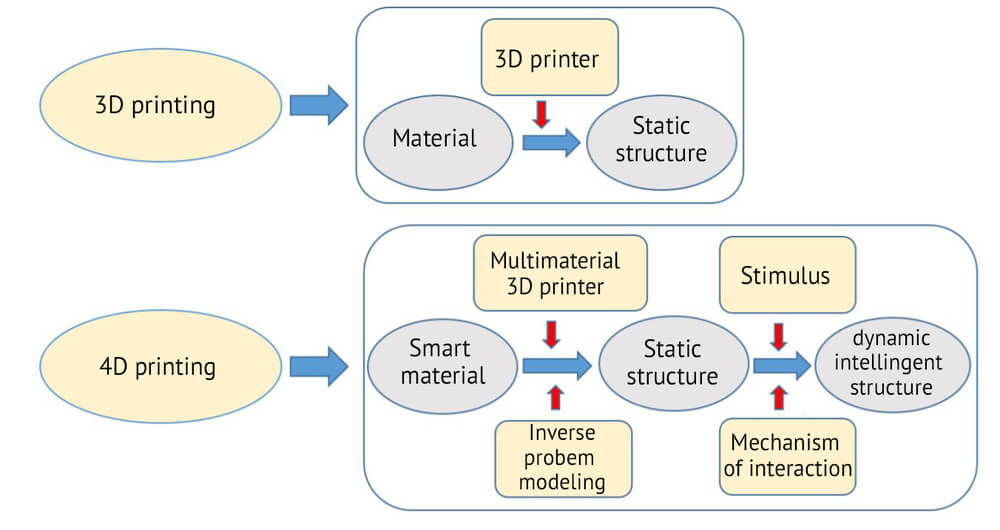

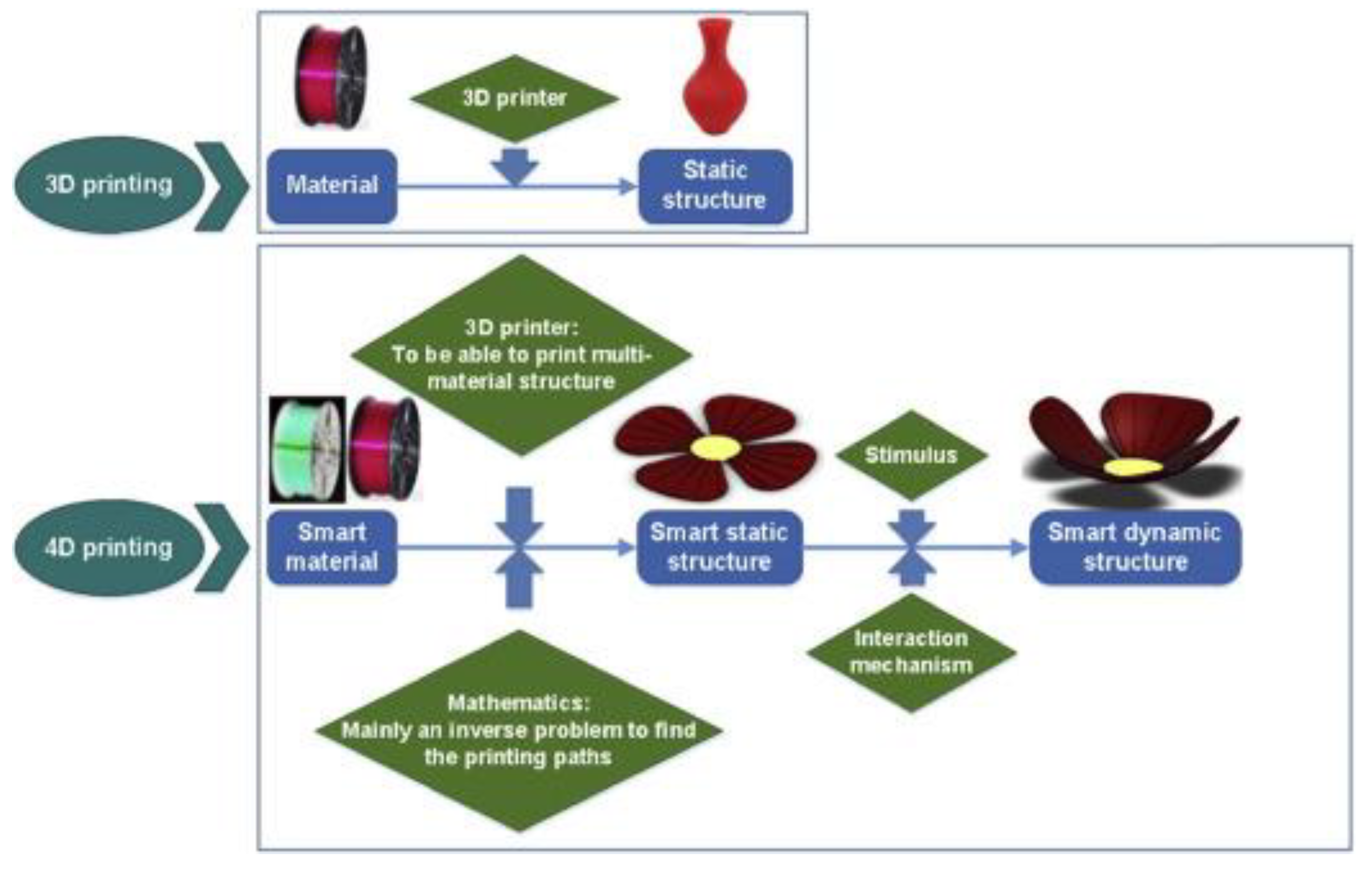

4D printing is one of the most groundbreaking innovations in advanced manufacturing, taking the capabilities of 3D printing to an entirely new level. While 3D printing creates static, solid objects, 4D printing creates objects that change shape, behavior, or function over time in response to environmental conditions such as heat, moisture, light, pressure, or magnetic fields.

In simple terms, 4D printing adds time as the fourth dimension, enabling objects to self-transform, self-assemble, bend, expand, contract, or even repair themselves without human intervention. This technology blends materials science, smart polymers, nanotechnology, physics, and computational design to create adaptive, programmable materials with enormous potential in industries such as healthcare, aerospace, construction, fashion, robotics, and environmental engineering.

This article provides a complete, beginner-friendly yet technical exploration of 4D printing, including how it works, current breakthroughs, real-world use cases, advantages, challenges, and what the future holds.

What Is 4D Printing?

4D printing uses smart materials that respond to external stimuli. These materials are designed to change their structure or shape over time after being 3D printed.

The “fourth dimension” refers to time or transformation, meaning that the object:

- Starts in one shape

- Is exposed to a trigger (heat, water, light, electricity, etc.)

- Then transforms into a programmed new shape or function

Unlike traditional manufacturing methods, 4D printing allows designers to embed “instructions” into the material, making it morph or adapt on its own when activated.

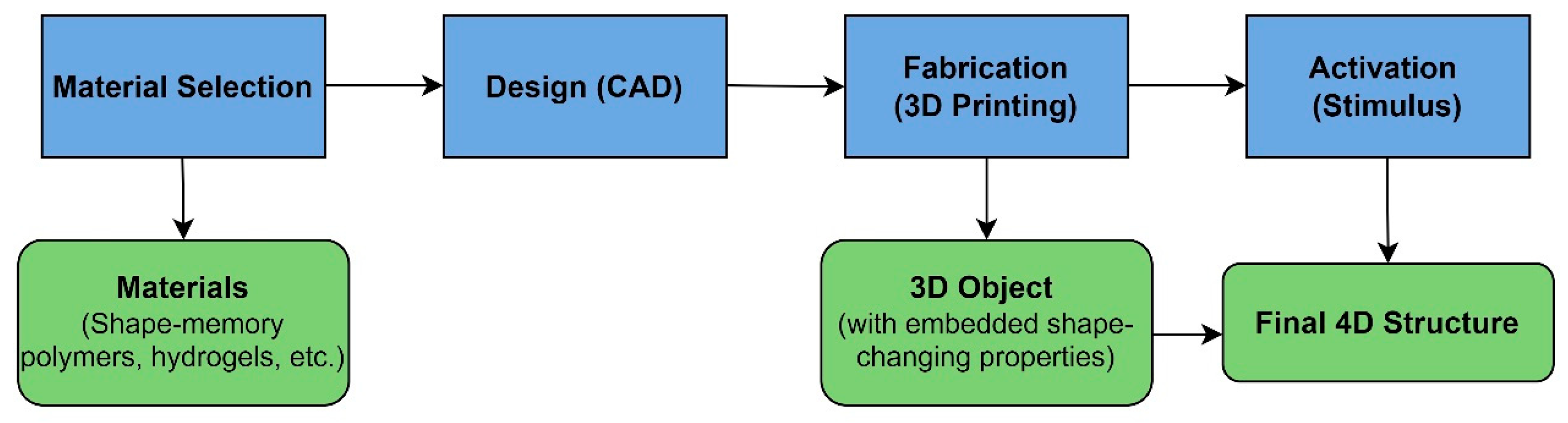

How 4D Printing Works

4D printing relies on a combination of material science, digital modeling, and environmental triggers. It works in several steps:

Step 1: Design the Transformation

Engineers use CAD and simulation tools to model the shape-shifting behavior. The design includes:

- Initial form

- Final form

- Path of transformation

- Trigger conditions

Algorithms help calculate how the material will behave at every stage.

Step 2: Select Smart Materials

4D printing uses advanced materials such as:

- Shape-memory polymers

- Hydrogels

- Thermal-responsive materials

- Light-responsive materials

- Magnetoresponsive composites

- Multi-material composites

These materials contain molecular structures that can shift when stimulated.

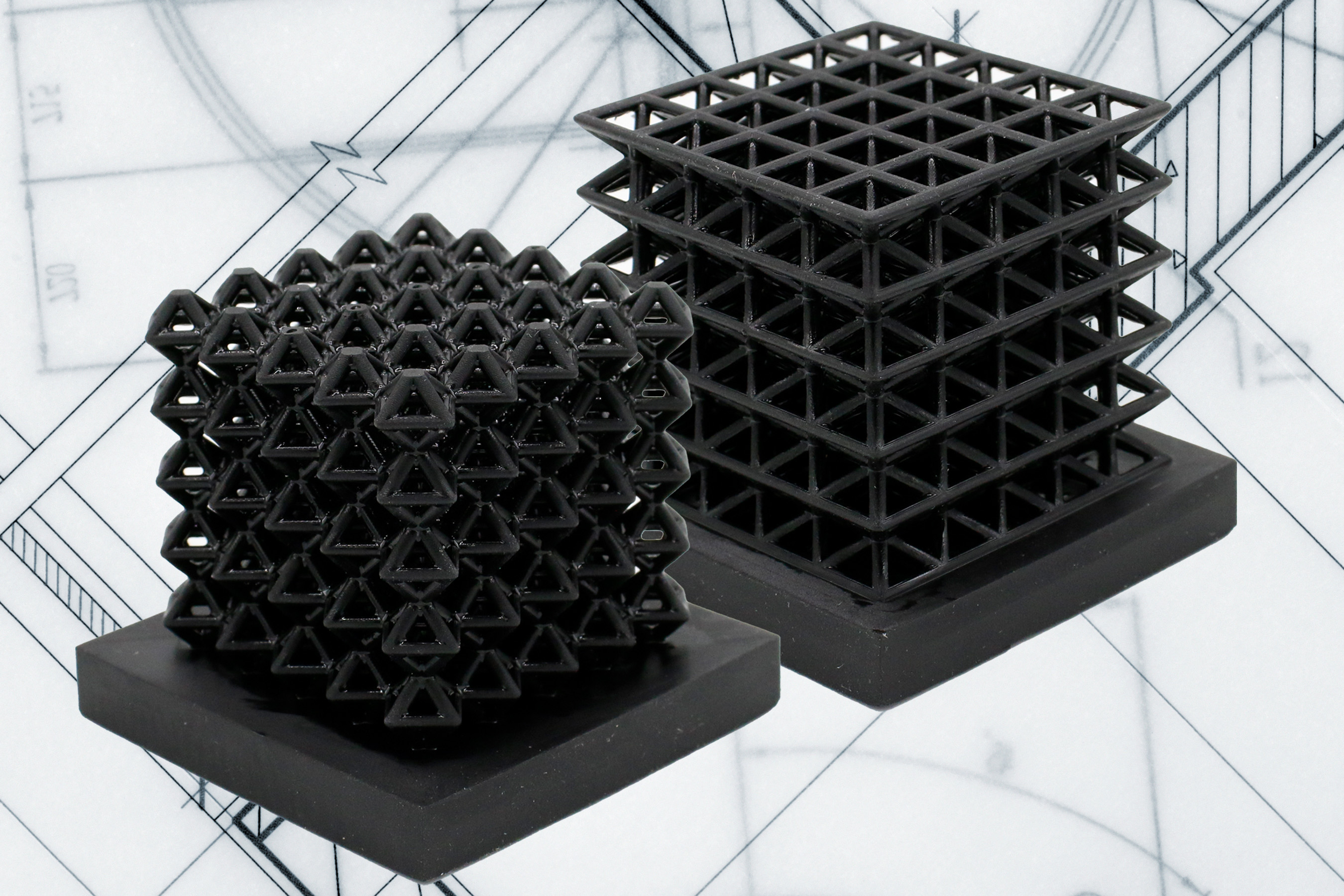

Step 3: Multi-Material 3D Printing

Printers deposit layers with variations in stiffness, elasticity, thickness, and orientation. The material composition determines how the object will later transform.

Step 4: Activation

Once printed, the object is exposed to a stimulus such as:

- Heat

- Water/moisture

- Light (UV, infrared)

- Electricity

- Magnetic fields

- pH changes

The object responds by changing shape or structure, performing its programmed transformation.

Key Technologies Enabling 4D Printing

Smart Polymers

These polymers change their physical properties in reaction to environmental changes.

Shape Memory Materials

These materials “remember” a predetermined shape and shift back to it when triggered.

Hydrogels

Water-absorbing materials able to swell or shrink in controlled ways.

Multi-Material Printing

4D printing relies heavily on printers capable of mixing different materials within the same object.

Computational Modeling

AI and simulation tools predict how materials will respond over time, allowing precise control.

Types of Transformations in 4D Printing

Different materials respond differently, creating a wide range of transformations.

Shape-Shifting

Objects bend, twist, curl, or expand.

Self-Assembly

Flat structures fold into 3D shapes automatically.

Self-Repair

Materials identify and heal cracks or damage.

Property Modification

Objects can change:

- Stiffness

- Permeability

- Elasticity

- Conductivity

Movement and Actuation

Some materials act like artificial muscles, capable of motion.

Breakthroughs in 4D Printing (2023–2025)

Recent advancements have brought 4D printing into practical applications.

Improved Smart Materials

New polymers can shift shape repeatedly without degradation.

Multi-Stimuli Materials

Materials that respond to more than one trigger allow more complex behavior.

Faster Reaction Times

Objects now change shape in seconds instead of hours.

Higher Durability

Smart materials are now stronger and more flexible, surviving thousands of transformation cycles.

Integration with AI

AI models help predict and optimize shape transformations with high accuracy.

Large-Scale 4D Printing

4D printing is no longer limited to small prototypes—construction-scale printed elements are emerging.

Applications of 4D Printing Across Industries

4D printing is unlocking new possibilities across multiple sectors. Here are the major fields where the technology is making an impact:

Healthcare and Medicine

Self-Expanding Stents

4D-printed stents can enter arteries in compact form and expand once inside the body.

Tissue Engineering

Smart scaffolds adjust stiffness and porosity to support cell growth.

Personalized Orthotics

Material adapts to body temperature or user movement.

Drug Delivery Devices

Capsules change shape to release medication at controlled intervals.

Surgical Tools

4D-printed instruments can soften or stiffen as required.

Aerospace and Aviation

4D printing enables lightweight, adaptive components such as:

Adaptive Airfoils

Wings that adjust shape for optimal aerodynamic performance.

Self-Repairing Materials

Aircraft parts that heal surface damage mid-flight.

Deployable Structures

Components that fold for compact storage then expand in space.

Thermal-Responsive Parts

Materials that adjust properties due to space temperature changes.

Construction and Architecture

4D printing could revolutionize sustainable building materials.

Self-Forming Structures

Flat materials that automatically transform into curved or complex shapes.

Moisture-Responsive Facades

Panels that open or close depending on humidity and temperature.

Earthquake-Resistant Components

Structures that flex instead of breaking.

Time-Adaptive Pipes

Pipes that expand or contract with temperature changes.

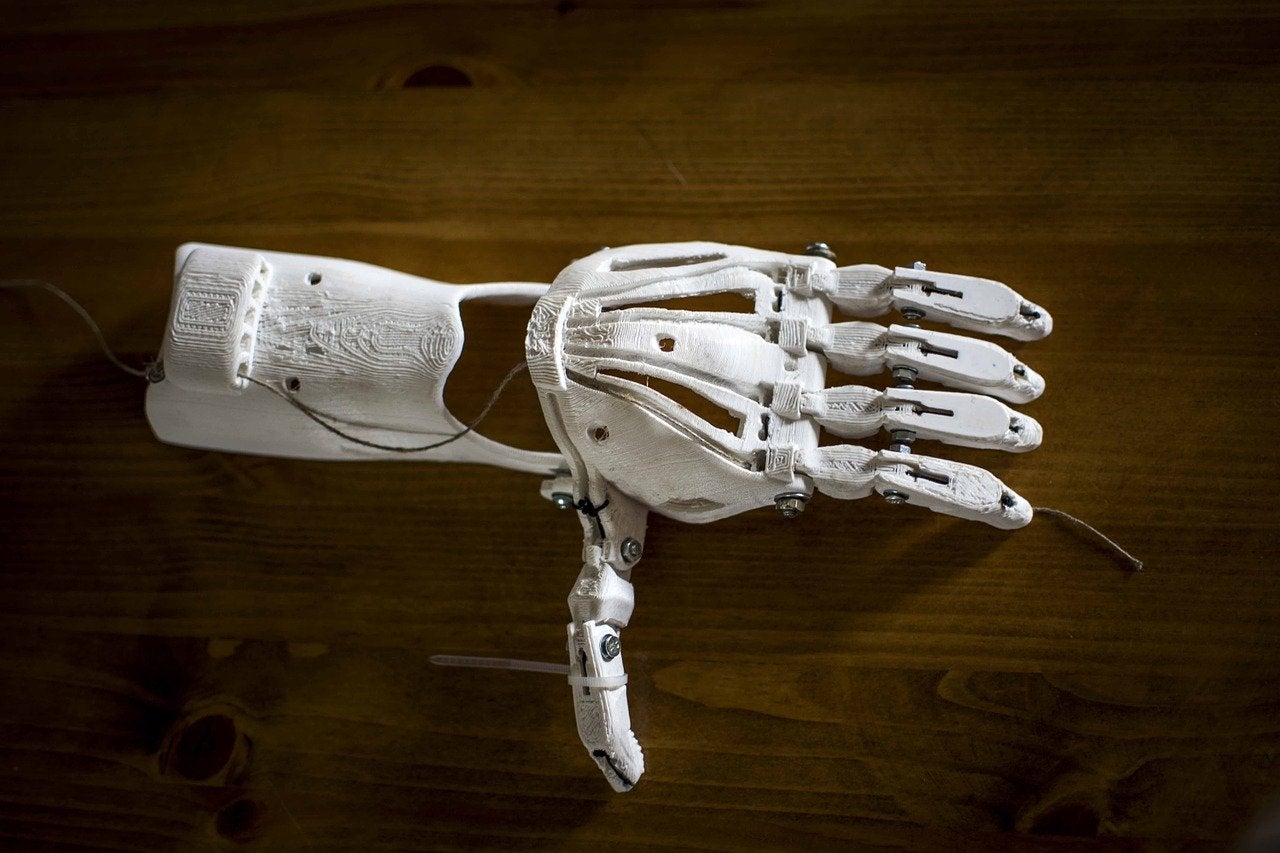

Robotics

4D printing merges robotics with soft, flexible materials.

Soft Robots

Actuated by heat or light instead of motors.

Artificial Muscles

Materials that contract or extend like human muscle tissue.

Shape-Shifting Grippers

Grippers that conform to any object shape.

Fashion and Wearables

4D printed clothing adapts to temperature or body movement.

Auto-Fitting Apparel

Garments reshape to fit any body type.

Temperature-Adaptive Fabric

Cooling or insulating depending on the environment.

Self-Folding Footwear

Shoes or accessories that adjust shape for comfort.

Environmental and Sustainability

Self-Actuating Water Valves

Open or close depending on flow pressure.

Smart Irrigation Systems

4D-printed structures react to soil moisture.

Eco-Friendly Materials

Biodegradable smart polymers reduce waste.

Advantages of 4D Printing

4D printing offers unique advantages compared to 3D printing or traditional manufacturing.

Adaptability

The ability of materials to adapt improves efficiency and longevity.

Space and Cost Savings

Objects can be printed in compact forms and expand when needed.

Self-Assembly

Reduces labor and manufacturing complexity.

Reduced Maintenance

Self-healing materials minimize repairs and downtime.

Improved Functionality

Objects can perform multiple tasks depending on environmental triggers.

Lightweight Structures

Ideal for aerospace and transportation.

Challenges and Limitations of 4D Printing

Despite promising progress, challenges remain.

Material Limitations

Smart materials can be expensive or difficult to manufacture.

Slow Transformation

Some objects still take minutes or hours to activate.

Durability Issues

Repeated transformations may weaken the structure.

High Cost

Research-grade 4D materials can be expensive.

Complex Modeling

Predicting shape shifts requires advanced simulation.

Limited Industrial Standards

Industry regulation and standardization are still developing.

Future of 4D Printing (2025–2040)

The future of 4D printing is incredibly promising and could fundamentally change manufacturing.

Highly Responsive Smart Materials

Materials will react instantly to triggers.

Fully Programmable Matter

Objects may reconfigure into multiple shapes based on needs.

Large-Scale 4D Printed Buildings

Self-assembling construction components.

Medical Implants That Evolve

Implants that grow, heal, or reshape with the body.

Intelligent Soft Robots

Soft robots that navigate complex environments autonomously.

Personalized Consumer Products

Wearables, devices, and clothing that adapt to the person wearing them.

Integration with AI-Driven Design

AI will optimize transformation patterns more efficiently than human designers.

Impact of 4D Printing on Society and Industry

4D printing will influence how products are designed, built, and used.

Manufacturing Efficiency

Less material waste due to automated shape transformation.

Lower Environmental Impact

Eco-friendly smart materials enable sustainable products.

Healthcare Breakthroughs

Adaptive implants and medical devices can improve patient outcomes.

Infrastructure Innovation

Buildings become more resilient to climate and environmental changes.

Disaster Response

Self-deploying structures and tools for emergencies.

Consumer Customization

Everyday products become more interactive and tailored.

Conclusion

4D printing is one of the most exciting innovations in modern engineering, blending advanced materials with digital design to create objects that move, adapt, and evolve over time. It represents a massive leap forward beyond traditional and 3D printing technologies, offering transformative applications in healthcare, aerospace, robotics, construction, and sustainability.

With rapid progress in smart materials, AI modeling, and multi-material printing, 4D printing is moving from scientific experimentation to real-world integration. In the coming decades, everything from buildings to implants to clothing may be capable of adapting to the environment or user needs at the molecular level.

4D printing is not just a manufacturing technique—it is the beginning of a future where materials themselves become intelligent.